I-ASTM A671 ngumbhobho wentsimbi owenziwe kwipleyiti yomgangatho wenqanawa yoxinzelelo,Ukuhlanganiswa koMbane-oWelded (EFW)kwiindawo ezinoxinzelelo oluphezulu kumaqondo obushushu asezantsi naphantsi.

Ngokukodwa ifanelekile kwizicelo ezifuna ukuzinza koxinzelelo oluphezulu kunye neempawu ezithile zobushushu obuphantsi.

Amaqhosha okukhangela

ASTM A671 Ubungakanani Uluhlu

Ukumakishwa kwe-ASTM A671

Ukuhlelwa kweBanga

Classification Class

Iimpahla ezingekasilwa

Amanqaku aPhambili eWelding

Unyango lobushushu kwiiklasi ezahlukeneyo

IiProjekthi zoMfuniselo ze-ASTM A671

Imbonakalo ye-ASTM A671

Ukutenxa okuvumelekileyo kubungakanani

Izicelo ze-ASTM A671 ye-Steel Tubing

Iimveliso zethu ezinxulumeneyo

ASTM A671 Ubungakanani Uluhlu

Uluhlu olucetyiswayo: iipayipi zensimbi kunye ne-DN ≥ 400 mm [16 in] kunye ne-WT ≥ 6 mm [1/4].

Isenokusetyenziswa kobunye ubungakanani bombhobho, ngaphandle kokuba iyahlangabezana nazo zonke ezinye iimfuno zolu nkcukacha.

Ukumakishwa kwe-ASTM A671

Ukuze uqonde ngcono i-ASTM A671, masiqale siqonde umxholo wayo wokumakisha.Oku kunceda ukucacisa ububanzi besicelo kunye neempawu zalo mgangatho.

Umzekelo wophawu lwesitshizi:

BOTOP EFW ASTM A671 CC60 -22 16"×SCH80 HEAT NO.4589716

I-BOTOP: Igama lomenzi.

EFW: Inkqubo yokuvelisa ityhubhu yentsimbi.

I-ASTM A671: Umgangatho oLawulayo we-Steel Tubing.

CC60-22: Izishunqulelo zebakala:cc60 kunye neklasi yama-22.

16" x SCH80: Ububanzi kunye noDonga olutyebileyo.

HUTSHULU NO.4589716: Hayi ubushushu.ukuveliswa kweetyhubhu zetsimbi.

Le yifomathi eqhelekileyo ye-ASTM A671 yokubhala ilebhile yokutshiza.

Akunzima ukufumana i-ASTM A671 kwibakala kunye nokuhlelwa kodidi lwesibini, emva koko ezi zintlu zimbini zimele ukuba yintoni intsingiselo.

Ukuhlelwa kweBanga

Ihlelwe ngokohlobo lwepleyiti esetyenziselwa ukuvelisa iityhubhu zentsimbi.

Amabakala ahlukeneyo amele ukubunjwa kweekhemikhali ezahlukeneyo kunye neempawu zomatshini zoxinzelelo oluhlukeneyo kunye neemeko zokushisa.

Ngokomzekelo, amanye amabakala ziintsimbi zekhabhoni ezicacileyo, ngelixa ezinye ziziintsimbi ezineentsimbi ezongeziweyo, ezifana neentsimbi zenickel.

| IBanga lombhobho | Uhlobo lweNsimbi | Ukucaciswa kwe-ASTM | |

| Hayi. | Ibanga/iklasi/uhlobo | ||

| CA 55 | ikhabhoni ecacileyo | A285/A285M | Gr C |

| CB 60 | ikhabhoni ecacileyo, ibulewe | A515/A515M | Gr 60 |

| CB 65 | ikhabhoni ecacileyo, ibulewe | A515/A515M | Gr 65 |

| CB 70 | ikhabhoni ecacileyo, ibulewe | A515/A515M | Gr 70 |

| CC 60 | ikhabhoni ecacileyo, ibulewe, ingqolowa entle | A516/A516M | Gr 60 |

| CC 65 | ikhabhoni ecacileyo, ibulewe, ingqolowa entle | A516/A516M | Gr 65 |

| CC 70 | ikhabhoni ecacileyo, ibulewe, ingqolowa entle | A516/A516M | Gr 70 |

| ICD70 | manganese-silicon, eqhelekileyo | A537/A537M | Cl 1 |

| ICD80 | i-manganese-silicon, icinyiwe kwaye inomsindo | A537/A537M | Cl 2 |

| CFA 65 | intsimbi ye-nickel | A203/A203M | Gr A |

| CFB 70 | intsimbi ye-nickel | A203/A203M | Gr B |

| CFD 65 | intsimbi ye-nickel | A203/A203M | Gr D |

| CFE 70 | intsimbi ye-nickel | A203/A203M | UGr E |

| CG 100 | 9% nickel | A353/A353M | |

| CH 115 | 9% nickel | A553/A553M | Uhlobo loku-1 |

| CJA 115 | intsimbi ye-alloy, yacinywa kwaye inomsindo | A517/A517M | Gr A |

| CJB 115 | intsimbi ye-alloy, yacinywa kwaye inomsindo | A517/A517M | Gr B |

| CJE 115 | intsimbi ye-alloy, yacinywa kwaye inomsindo | A517/A517M | UGr E |

| CJF 115 | intsimbi ye-alloy, yacinywa kwaye inomsindo | A517/A517M | Gr F |

| CJH 115 | intsimbi ye-alloy, yacinywa kwaye inomsindo | A517/A517M | Gr H |

| CJP 115 | intsimbi ye-alloy, yacinywa kwaye inomsindo | A517/A517M | UGr P |

| CK 75 | carbon-manganese-silicon | A299/A299M | Gr A |

| I-CP85 | intsimbi ye-alloy, ukuqina kweminyaka, ukucima kunye nokushisa kwemvula kuphathwe | A736/A736M | Gr A, udidi lwesi-3 |

Classification Class

Iityhubhu zihlelwa ngokohlobo lonyango lobushushu abalufumanayo ngexesha lokwenziwa kwenkqubo yokuvelisa nokuba ngaba bahlolwa ngeradiographical kunye noxinzelelo oluvavanyiweyo.

Iindidi ezahlukeneyo zibonisa iindlela ezahlukeneyo zonyango lobushushu kwiityhubhu.

Imizekelo ibandakanya ukuqheleka, ukunciphisa uxinzelelo, ukucima, kunye nokucaphuka.

| Iklasi | Unyango lobushushu kumbhobho | Iradiyografi, bona inqaku: | Uvavanyo loxinzelelo, bona inqaku: |

| 10 | akukho nanye | akukho nanye | akukho nanye |

| 11 | akukho nanye | 9 | akukho nanye |

| 12 | akukho nanye | 9 | 8.3 |

| 13 | akukho nanye | akukho nanye | 8.3 |

| 20 | kuthotyiwe uxinzelelo, jonga ku-5.3.1 | akukho nanye | akukho nanye |

| 21 | kuthotyiwe uxinzelelo, jonga ku-5.3.1 | 9 | akukho nanye |

| 22 | kuthotyiwe uxinzelelo, jonga ku-5.3.1 | 9 | 8.3 |

| 23 | kuthotyiwe uxinzelelo, jonga ku-5.3.1 | akukho nanye | 8.3 |

| 30 | iqhelekile, jonga ku-5.3.2 | akukho nanye | akukho nanye |

| 31 | iqhelekile, jonga ku-5.3.2 | 9 | akukho nanye |

| 32 | iqhelekile, jonga ku-5.3.2 | 9 | 8.3 |

| 33 | iqhelekile, jonga ku-5.3.2 | akukho nanye | 8.3 |

| 40 | iqhelekile kwaye inomsindo, jonga ku-5.3.3 | akukho nanye | akukho nanye |

| 41 | iqhelekile kwaye inomsindo, jonga ku-5.3.3 | 9 | akukho nanye |

| 42 | iqhelekile kwaye inomsindo, jonga ku-5.3.3 | 9 | 8.3 |

| 43 | iqhelekile kwaye inomsindo, jonga ku-5.3.3 | akukho nanye | 8.3 |

| 50 | ucime wacaphuka, jonga ku-5.3.4 | akukho nanye | akukho nanye |

| 51 | ucime wacaphuka, jonga ku-5.3.4 | 9 | akukho nanye |

| 52 | ucime wacaphuka, jonga ku-5.3.4 | 9 | 8.3 |

| 53 | ucime wacaphuka, jonga ku-5.3.4 | akukho nanye | 8.3 |

| 70 | olucinyiweyo kunye nobushushu bemvula bunyangwe | akukho nanye | akukho nanye |

| 71 | olucinyiweyo kunye nobushushu bemvula bunyangwe | 9 | akukho nanye |

| 72 | olucinyiweyo kunye nobushushu bemvula bunyangwe | 9 | 8.3 |

| 73 | olucinyiweyo kunye nobushushu bemvula bunyangwe | akukho nanye | 8.3 |

Ukushisa kokusetyenziswa kufuneka kuqatshelwe xa ukhetha izinto.Ireferensi inokwenziwa kwingcaciso ye-ASTM A20/A20M.

Iimpahla ezingekasilwa

Iipleyiti ezikumgangatho ophezulu kwiinqanawa zoxinzelelo, iinkcukacha zeentlobo, kunye nemigangatho yokubulawa inokufumaneka kwitheyibhile kwiUkuhlelwa kweBangangaphezulu.

Amanqaku aPhambili eWelding

I-Welding: Ii-Seams ziya ku-welding kabini, ukungena ngokupheleleyo.

Ukuwelda kuya kwenziwa ngokuhambelana nemigaqo echazwe kwiCandelo IX le-ASME Boiler kunye neKhowudi yeVessel yoxinzelelo.

I-welds iya kwenziwa ngesandla okanye ngokuzenzekelayo ngenkqubo yombane ebandakanya ukubekwa kwesinyithi.

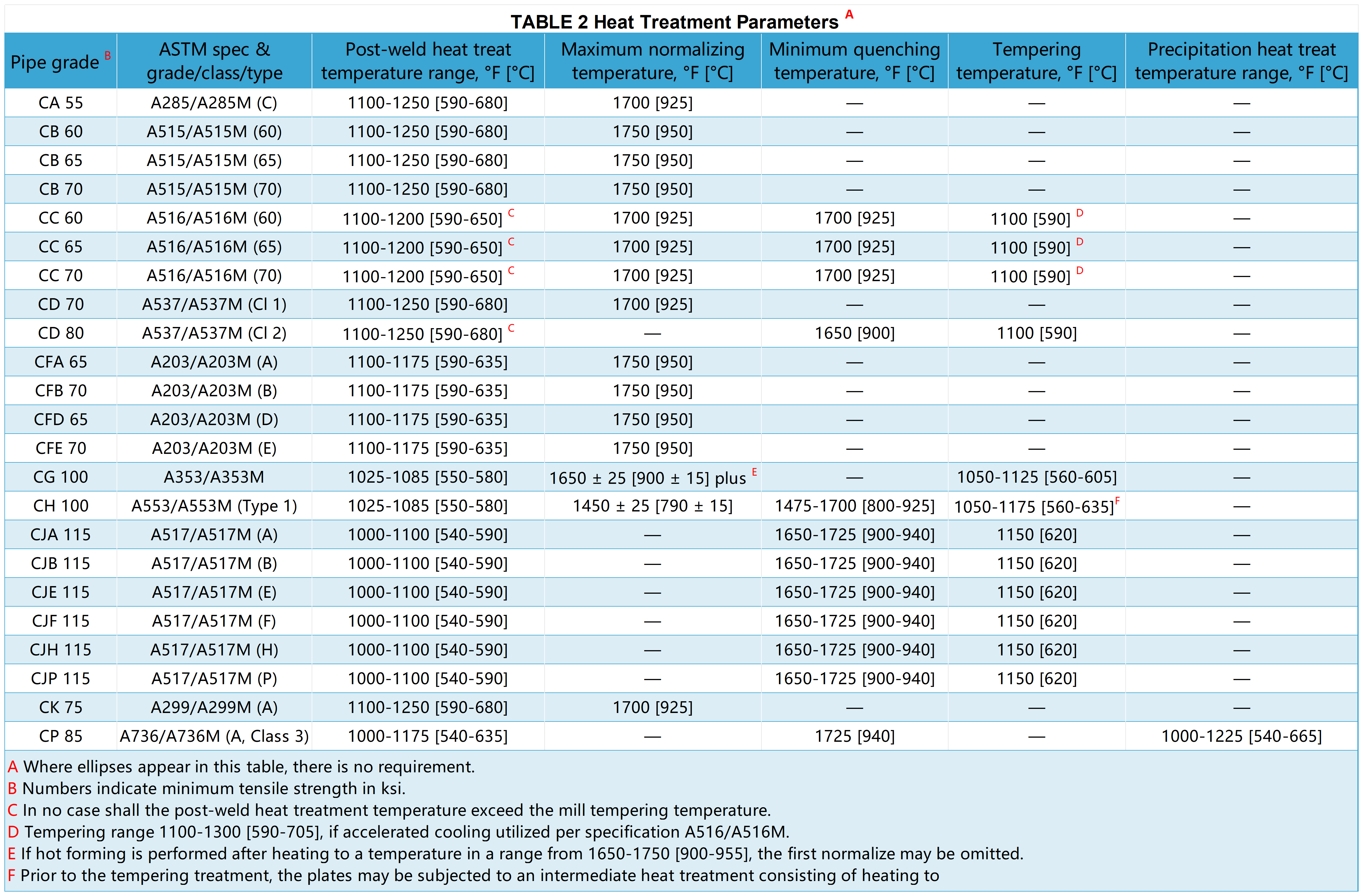

Unyango lobushushu kwiiklasi ezahlukeneyo

Zonke iiklasi ngaphandle kwe-10, 11, 12, kunye ne-13 ziya kunyangwa ubushushu kwiziko elilawulwa ukuya ku-±25 °F[± 15°C].

Iiklasi 20, 21, 22, kunye 23

Iyakufudunyezwa ngokufanayo kwiqondo lobushushu obungemva kweweld eliboniswe kwiThebhile 2 ubuncinane be-1 h/in.[0.4 h/cm] ubukhulu okanye i-1 h, nayiphi na enkulu.

Iiklasi 30, 31, 32, kunye nama-33

Uya kufudunyezwa ngokufanayo kwiqondo lobushushu kuluhlu lwe-austenitizing kwaye ungadluli ubushushu obuphezulu obuqhelekileyo obubonakaliswe kwiThebhile 2 kwaye emva koko ipholiswe emoyeni kwiqondo lobushushu begumbi.

Iiklasi 40, 41, 42, kunye nama-43

Umbhobho uya kuba yinto eqhelekileyo.

Umbhobho uza kufudunyezwa kwakhona kwiqondo lobushushu elibonakaliswe kwiThebhile 2 njengobuncinane kwaye ugcinwe kwiqondo lobushushu ubuncinane be-0.5 h/in.[0.2 h/cm] ubukhulu okanye i-0.5 h, nayiphi na enkulu, kunye nomoya- ipholile.

Iiklasi 50, 51, 52, kunye nama-53

Umbhobho uya kutshiswa ngokufanayo kumaqondo obushushu ngaphakathi koluhlu lwe-austenitizing kwaye ungagqithisi ubushushu bokucima ubuninzi obuboniswe kwiThebhile 2.

Emva koko, cima emanzini okanye ngeoli.Emva kokucima, umbhobho uya kuhlaziywa kwiqondo lokushisa elincinci eliboniswe kwiThebhile 2 kwaye ligcinwe apho.

iqondo lobushushu ubuncinane be-0.5 h/intshi [0.2 h/cm] ubukhulu okanye i-0.5 h, leliphi na elikhulu ngakumbi, nelipholiswe ngumoya.

Iiklasi 70, 71, 72, kunye nama-73

Imibhobho iyaifudunyezwe ngokufanayo kwiqondo lobushushu kuluhlu lwe-austenitizing, olungagqithiyo kubushushu obuphezulu bokucima obuboniswe kwiThebhile 2, kwaye emva koko lucinywe emanzini okanye kwi-oyile.

Emva kokucima umbhobho uya kuphinda ufudunyezwe kwi-precipitation heat treatment range eboniswe kwiThebhile 2 ixesha eliza kumiselwa ngumenzi.

IiProjekthi zoMfuniselo ze-ASTM A671

Ukuqulunqwa kwemichiza

Ngokweemfuno ezihambelanayo zemigangatho yokuphunyezwa kwezinto ezikrwada, uhlalutyo lokubunjwa kweekhemikhali, iziphumo zovavanyo lokuhlangabezana neemfuno eziqhelekileyo.

Uvavanyo loxinzelelo

Yonke imibhobho edityanisiweyo eyenziwe ngolu hlobo kufuneka ibe novavanyo lwe-cross-weld tensile emva konyango lokugqibela lobushushu, kwaye iziphumo kufuneka zihambelane nesiseko semathiriyeli yokuqina kokuqina kwemathiriyeli yepleyiti echaziweyo.

Ukongeza, amaBanga e-CD XX kunye ne-CJ XXX, xa ezi ziKlasi 3x, 4x, okanye 5x, kunye neBanga le-CP le-6x kunye ne-7x liya kuba novavanyo lwe-metal metal tensile olunqamlezayo olwenziwa kwiisampuli ezisikwe kumbhobho ogqityiweyo.Iziphumo zolu vavanyo ziya kuhlangabezana neyona mfuno isezantsi yovavanyo yomatshini wenkcazo yepleyiti.

Transverse Guided Weld Bend Test

Uvavanyo lokugoba luya kwamkeleka ukuba akukho zintanda okanye ezinye iziphene ezidlulayo1/8in. [3 mm] kulo naliphi na icala zikhona kwintsimbi edibeneyo okanye phakathi kwentsimbi kunye nesiseko sesinyithi emva kokugoba.

Iintanda ezivela ecaleni komfanekiso ngexesha lovavanyo, kwaye ezingaphantsi1/4ngaphakathi. [6 mm] imilinganiselo kulo naliphi na icala ayisayi kuqwalaselwa.

Uvavanyo loxinzelelo

Iiklasi X2 kunye X3 umbhobho ziya kuvavanywa ngokuhambelana Specification A530/A530M, Hydrostatic Test Requirements.

Uviwo lweRadiographic

Ubude obupheleleyo beweld nganye yeeKlasi X1 kunye ne-X2 buya kujongwa ngeradiographically ngokuhambelana kwaye kuhlangabezene neemfuno ze-ASME Boiler kunye neKhowudi yeVessel yoxinzelelo, iCandelo VIII, umhlathi UW-51.

Uvavanyo lwe-radiographic lunokwenziwa ngaphambi konyango lobushushu.

Imbonakalo ye-ASTM A671

Umbhobho ogqityiweyo awuyi kuba neziphene ezinobungozi kwaye uya kuba nesiphelo esifana nomsebenzi.

Ukutenxa okuvumelekileyo kubungakanani

| Ezemidlalo | Ukunyamezela Ixabiso | Phawula |

| Ngaphandle Ububanzi | ±0.5% | Ngokusekelwe kumlinganiselo ojikelezayo |

| Ngaphandle kwe-Roundness | 1%. | Umahluko phakathi kweedayamitha ezinkulu nezincinci zangaphandle |

| Ulungelelwaniso | 1/8 kwi [3 mm] | Ukusebenzisa i-10 ft [3 yeemitha] edge ethe tye ebekwe ukuze iziphelo zombini zidibane nombhobho |

| Ukutyeba | 0.01 kwi [0.3 mm] | Ubuncinane bobunzima bodonga bungaphantsi kobungqingqwa obuxeliweyo |

| Ubude | 0 - +0.5in [0 - +13mm] | iziphelo ezingenakwenziwa |

Izicelo ze-ASTM A671 ye-Steel Tubing

Ishishini laMandla

Isetyenziselwa ukuthutha ulwelo lwe-cryogenic kwizityalo zonyango lwegesi yendalo, iindawo zokucokisa, kunye neendawo zokulungisa imichiza.

IiNkqubo zeFriji kwimizi-mveliso

Ukusetyenziswa kwinxalenye ye-cryogenic yefriji kunye neenkqubo zokumisa umoya ukuqinisekisa ukuzinza kunye nokhuseleko lwenkqubo.

Izinto eziluncedo

Ukugcina kunye neendawo zokuthutha iigesi ezimanzi.

Ukwakha kunye noKwakha

Ukusetyenziswa kwiiprojekthi zeziseko ezingundoqo kumaqondo obushushu aphantsi okanye iimeko zokusingqongileyo ezigqithisileyo, ezifana nokwakhiwa kokugcina okubandayo.

Singomnye wemibhobho yentsimbi yekhabhoni ehamba phambili kunye nabavelisi bemibhobho yentsimbi engenamthungo kunye nabanikezeli abavela eChina, kunye noluhlu olubanzi lwemibhobho yentsimbi ephezulu kwisitokhwe, sizimisele ukukunika uluhlu olupheleleyo lwezisombululo zemibhobho yentsimbi.Ukufumana iinkcukacha ezithe kratya zemveliso, nceda ukhululeke ukudibana nathi, sijonge phambili ekuncedeni ukuba ufumane iinketho ezingcono kakhulu zemibhobho yentsimbi kwiimfuno zakho!

Iithegi: ASTM a671, efw, cc 60, iklasi 22, ababoneleli, abavelisi, iifektri, abagcini bempahla, iinkampani, ihoseyili, thenga, ixabiso, ucaphulo, isambuku, intengiso, ixabiso.

Ixesha lokuposa: Apr-19-2024