I-BS EN 10210 iityhubhu zentsimbiNgamacandelo ashushu agqityiweyo angenamgongxo weentsimbi ezingalukwanga kunye nezicolekileyo zoluhlu olubanzi lwezicelo zezakhiwo kunye nezakhiwo zoomatshini.Iqulathe amacandelo angqukuva, isikweri, uxande, kunye nombhoxo.

I-EN 10210 kunye ne-BS EN 10210 yimigangatho efanayo kodwa inemibutho eyahlukeneyo.

Amaqhosha okukhangela

Ulwahlulo lwe-BS EN 10210

BS EN 10210 Ubungakanani Uluhlu

Iimpahla ezingekasilwa

I-BS EN 10210 Igama leNsimbi

Imiqathango yokuhanjiswa kwe-BS EN 10210

Ukubunjwa kwemichiza ye-BS EN 10210

IiPropati zoomatshini ze-BS EN 10210

Iimvavanyo zempembelelo

Ukuweldability

Ukunyamezelwa kweDimensional

Imbonakalo yoMphezulu

Iigalvanized

Ukulungiswa kweziphene zoMphezulu

I-BS EN 10210 Ukumakisha

Usetyenziso

Iimveliso zethu ezinxulumeneyo

Ulwahlulo lwe-BS EN 10210

NgoHlobo Lwentsimbi

Iintsimbi ezikhethekileyo ezingafakwanga kunye nezidibeneyo

Iintsimbi ezingafakwanga: S235JRH, S275JOH ,S275J2H, S355JOH, S355J2H, S355K2H , S275NH,S275NLH,S355NH,S355NLH.

Iintsimbi ezidityanisiweyo ezikhethekileyoInkcazo: S420NH,S420NLH,S460NH,S460NLH.

Indlela elula yokuchonga: egameni lentsimbi, ukuba amandla emveliso yesalathisi aqala ngenani '4', kwintsimbi ye-alloy.

NgeNkqubo yokuVelisa

Amacandelwana angumngxunya wesakhiwo kufuneka enziweiinkqubo ezingenamthungo okanye ezidityanisiweyo.

I-Seamless ibandakanya: i-hot-finished and cold-finished

Iintsimbi eziqhelekileyo ziquka i-Electric Resistance Welding (ERW) kunye ne-Arc Welding ephantsi kwamanzi (SAW): LSAW, SSAW.

Amacandelwana adityaniswe ngombane aqhelekileyo awafuni ukuchetywa kwe weld yangaphakathi.

NgokweMilo enqamlezileyo

CHS: amacandelo angenanto ajikelezayo;

RHS: amacandelo angaphantsi kwesikwere okanye uxande;

EHS: amacandelo e-elliptical hollow;

Eli nqaku liququzelelwe yi-circular cross-section (CHS) yomxholo ofanelekileyo.

BS EN 10210 Ubungakanani Uluhlu

Ubunzima bodonga: ≤120mm

Idayimitha yangaphandle:

Round (CHS): Idayimitha yangaphandle≤2500 mm;

Isikwere (RHS): Ububanzi bangaphandle≤ 800 mm × 800 mm;

Uxande (RHS): Ububanzi bangaphandle≤750 mm × 500 mm;

I-Oval (EHS): I-diameter yangaphandle≤ 500 mm × 250 mm.

Iimpahla ezingekasilwa

Intsimbi engafakwanga kunye necolekileyo.

Intsimbi engalukanga iimpawu ezine ezithi JR, JO, J2, kunye ne K2 zichaziwe.

Iintsimbi ezintle zengqolowa: iimpawu ezine ze-N kunye ne-NL zichazwe.

Iintsimbi eziziinkozo ezintle ziziintsimbi ezinokwakheka okuziinkozo, ezinobungakanani bengqolowa ye-ferrite ≥ 6.

I-BS EN 10210 Igama leNsimbi

Kwiziqendu zentsimbi ezingenalo i-alloy ukutyunjwa kwensimbi kubandakanya

Umzekelo: BS EN 10210-S275J0H

inezahlulo ezine:S, 275, J0, kunye noH.

1.S: ibonisa ukuba intsimbi yolwakhiwo.

2.Ixabiso lamanani(275): ubukhulu ≤ 16mm ngokobuncinane obuchaziweyo bamandla esivuno, kwiMPa.

3.JR: ibonisa ukuba kwiqondo lokushisa kwigumbi elineempembelelo ezithile;

J0: ibonisa ukuba ku-0 ℃ ngeempawu zempembelelo ezithile;

J2 okanye K2: iboniswe kwi -20 ℃ eneempawu zempembelelo ezithile;

4.H: ibonisa amacandelo angenanto.

Amacandelo entsimbi yolwakhiwo lwentsimbi ecolekileyo, ukutyunjwa kwentsimbi kubandakanya

Umzekelo: EN 10210-S355NLH

Inezahlulo ezintlanu:S, 355, N, L, kunye noH.

1. S: ibonisa intsimbi yolwakhiwo.

2. Ixabiso lamanani(355): Ubukhulu ≤ 16mm ubuncinane obuchaziweyo bamandla esivuno, iyunithi yiMPa.

3. N: ukuqengqeleka okusemgangathweni okanye okusemgangathweni.

4. L: iipropati zempembelelo ezithile kwi -50 °C.

5.H: ibonisa icandelo elingenanto.

Imiqathango yokuhanjiswa kwe-BS EN 10210

JR, J0, J2 kunye ne-K2 - kushushu kugqityiwe.

N kunye ne-NL - eqhelekileyo.I-normalized ibandakanya i-normalized rolled.

JR, J0, J2 kunye ne-K2 - eshushu yasebenza

I-N kunye ne-NL - Ukulungelelanisa.I-normalizing ibandakanya ukuqengqeleka okuqhelekileyo.

Kusenokuba yimfuneko kumacandelo angenamngxunya angenamthungo anobunzima bodonga ngaphezulu kwe-10 mm, okanye xa iT/D ingaphezulu kwe-0,1, ukusebenzisa ukupholisa okukhawulezileyo emva kokwenza i-austenitizing ukufezekisa ubume obucetyiweyo, okanye ukucinywa kolwelo kunye nokufudumeza ukufikelela komatshini ochaziweyo. iipropati.

Kumacandelo angenamgongxo anobunzima bodonga obudlula i-10 mm, okanye xa i-T/D ingaphezulu kwe-0.1, ukupholisa okukhawulezileyo emva kokwenziwa kwe-austenitization kunokufuneka ukuphumeza isakhiwo esinqwenelekayo, okanye ukucinywa kolwelo kunye nokufudumeza ukufikelela kwiipropati ezichaziweyo zoomatshini.

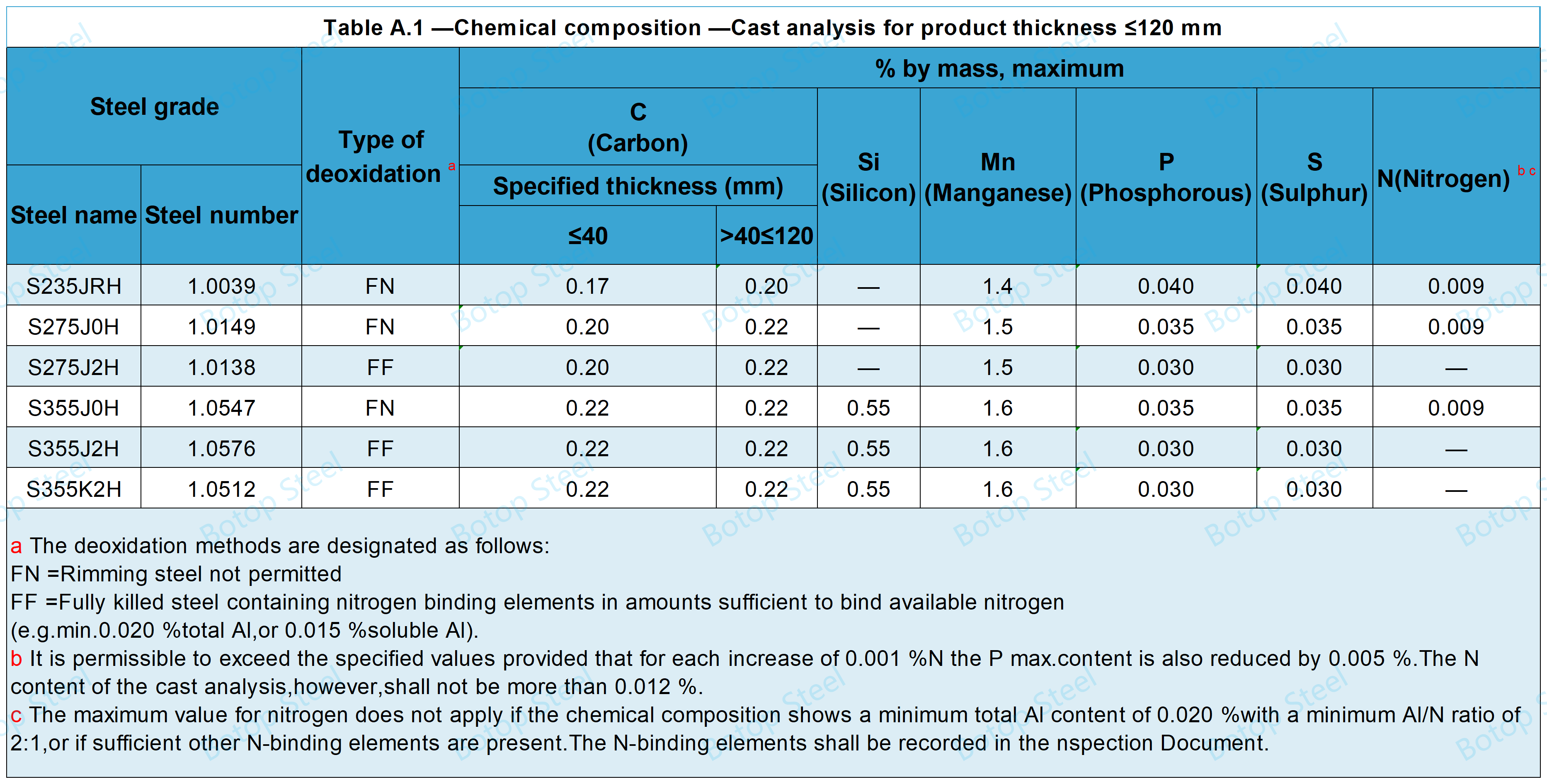

Ukubunjwa kwemichiza ye-BS EN 10210

Iintsimbi ze-non-alloy - Ukubunjwa kweekhemikhali

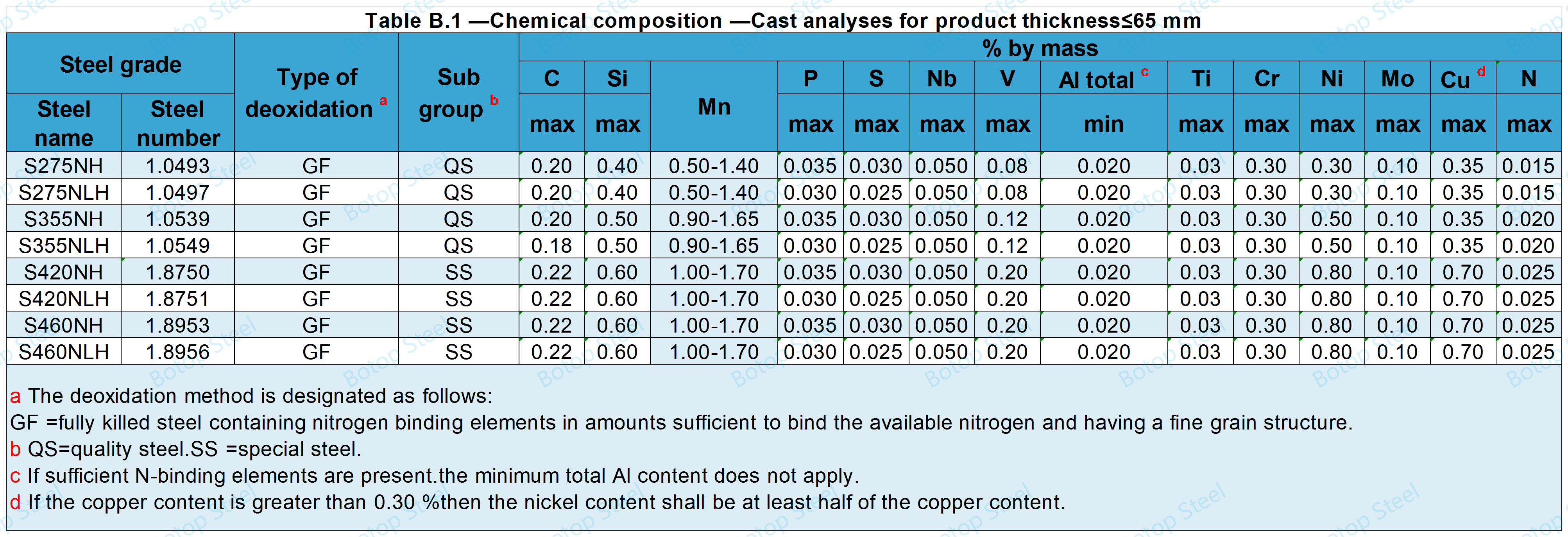

Fine Grain Steels - Ukubunjwa kwemichiza

Xa kumiselwa i-CEV le fomyula ilandelayo iya kusetyenziswa:

CEV=C+Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15

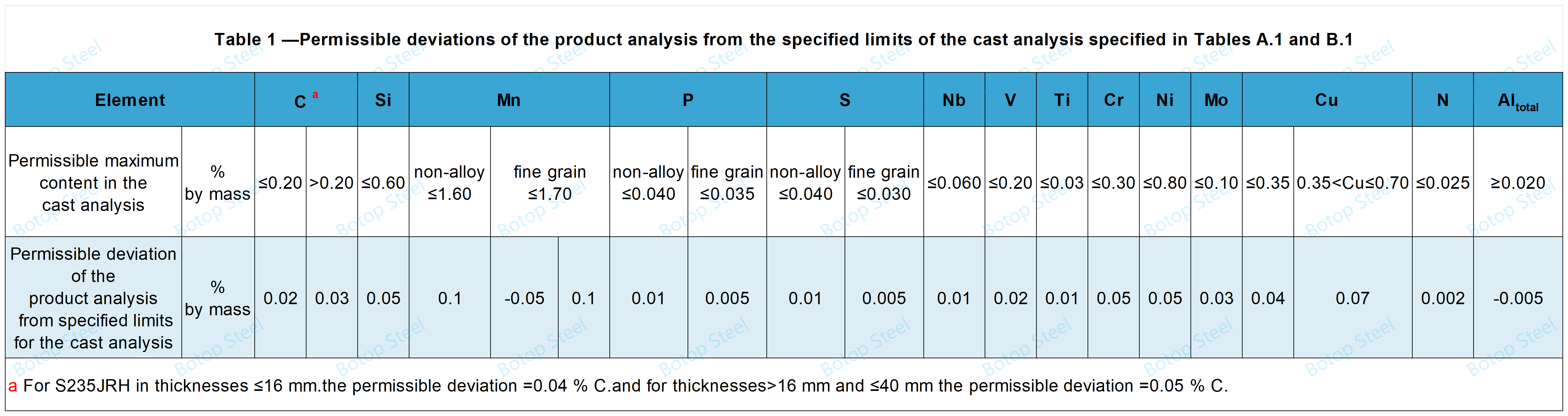

Ukutenxa ekuBumbeni kweMichiza

IiPropati zoomatshini ze-BS EN 10210

Ukuthomalalisa uxinzelelo kuxinzelelo olungaphezulu kwama-580 °C okanye ngaphezulu kweyure enye kunokukhokelela ekuwohlokeni kweempawu zoomatshini.

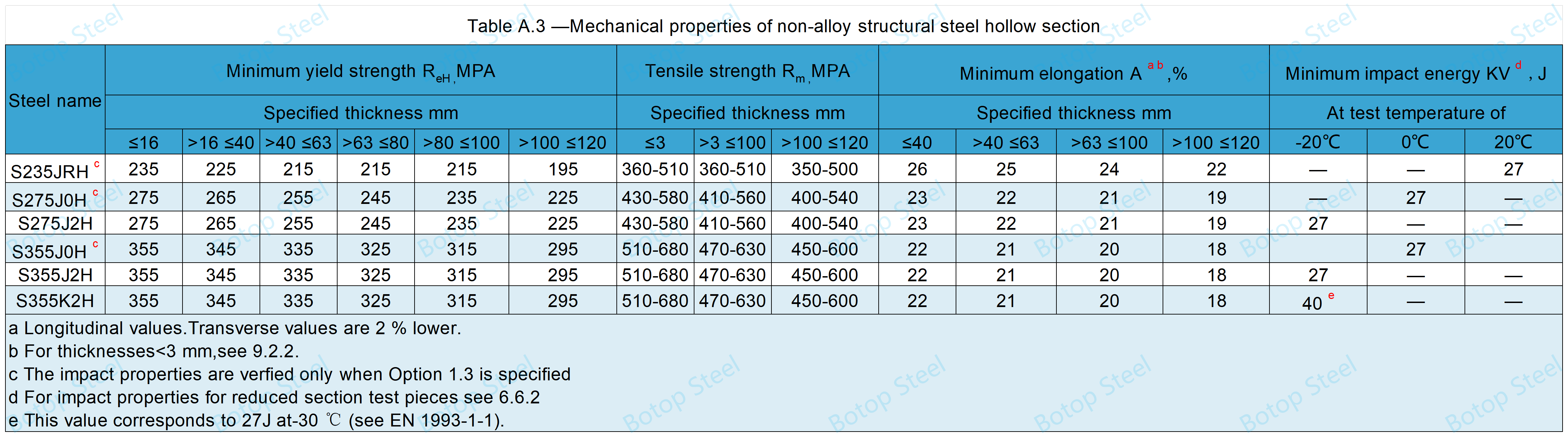

Iintsimbi ze-non-alloy - iiPropati zoomatshini

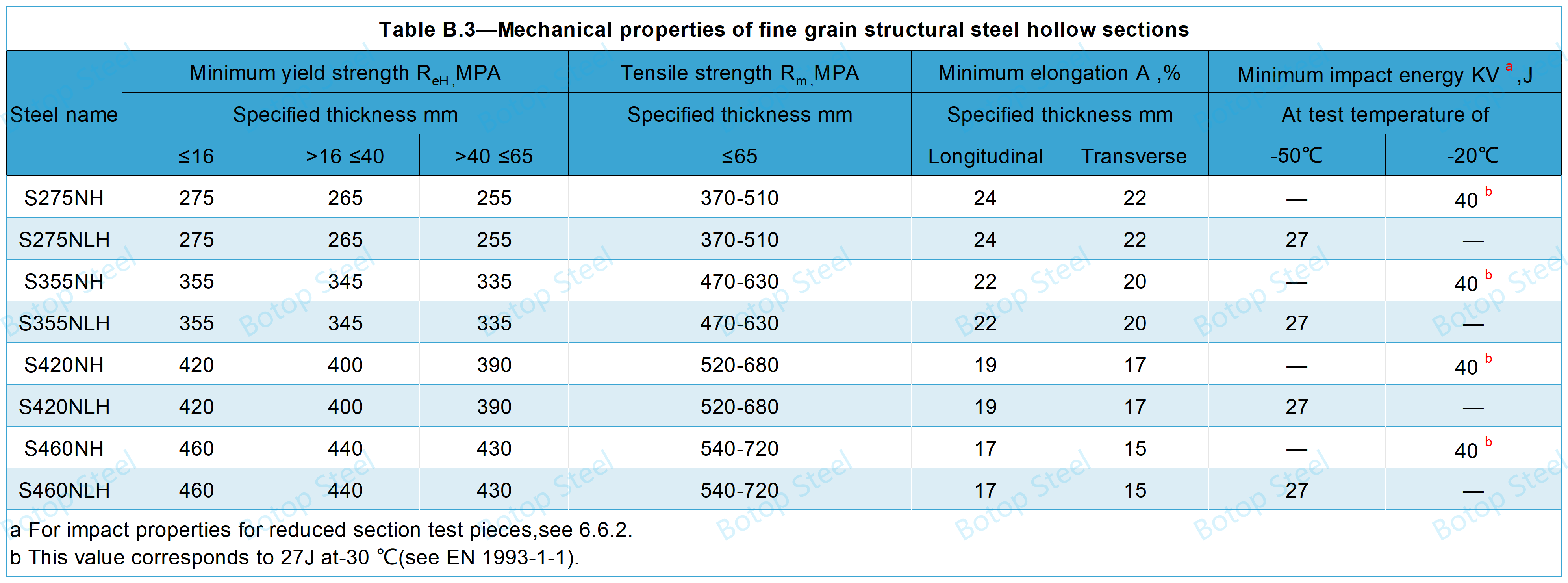

Fine Grain Steels - Mechanical Properties

Iimvavanyo zempembelelo

Uvavanyo lwempembelelo alufunwa xa ubukhulu obuchaziweyo < yi-6 mm.

Iisampulu ezikumgangatho oqhelekileyo we-V ngokwe-EN 10045-1 ziya kusetyenziswa.

Ukuba ubukhulu bemveliso yegama abunelanga ukulungiselela imizekelo esemgangathweni, iimvavanyo ziya kuqhutywa kusetyenziswa imizekelo enobubanzi obungaphantsi kwe-10 mm, kodwa ingabi ngaphantsi kwe-5 mm.

Ukuweldability

Iintsimbi kwi-BS EN 10210 ziyakwazi ukuwelda.

I-EN 1011-1 kunye ne-EN 1011-2 ichaza iimfuno ngokubanzi kwiimveliso ezidityanisiweyo.

Ukuqhekeka okubandayo kwindawo ye-weld ngowona mngcipheko uphambili njengoko ubukhulu bemveliso, inqanaba lamandla, kunye nokunyuka kwe-CEV.

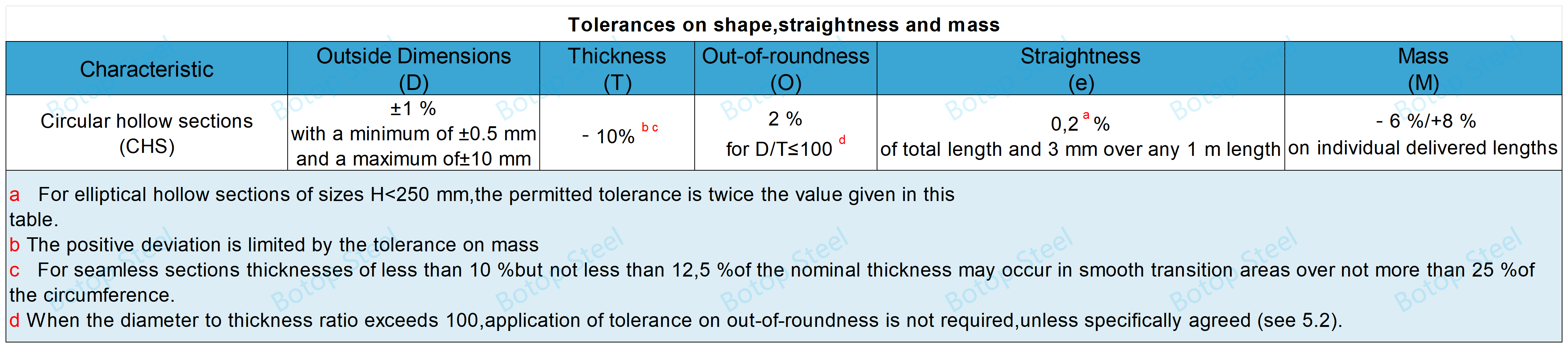

Ukunyamezelwa kweDimensional

Ukunyamezelana kwiMilo, ukuTwa kunye noMisa

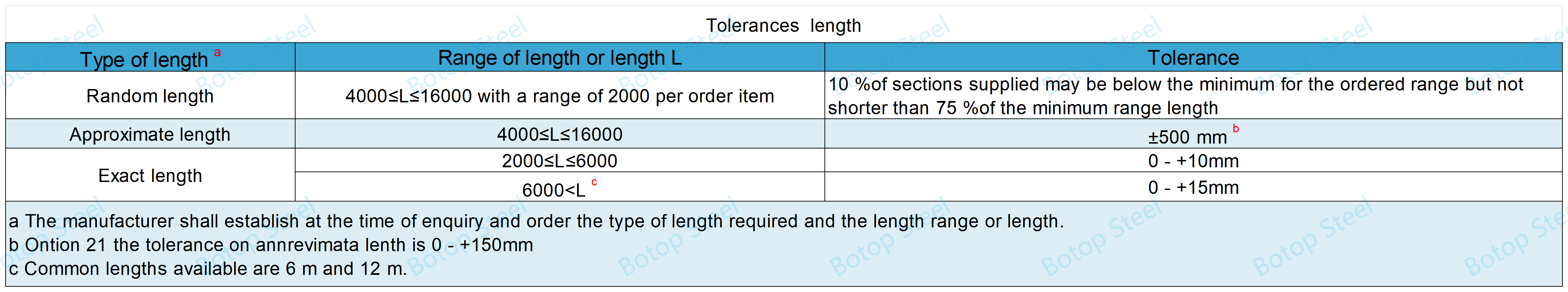

Ukunyamezela Ubude

Umthungo Ubude be-SAW Weld

Ukunyamezelana kubude bomthungo we-weld wangaphakathi nangaphandle we-arc entywiliselwe amacandelo aholoholo.

| Ukutyeba, T | Ubude be-weld bead, mm |

| ≤14,2 | 3.5 |

| >14,2 | 4.8 |

Umgangatho we-BS EN 10210 ugubungela zombini icandelo elingenamthungo kunye ne-welded eshushu eligqityiweyo.Iinkqubo ze-welding eziphambili zi-resistance welding (ERW) kunye ne-arc welding ephantsi kwamanzi (SAW).I-welds kwimibhobho yensimbi ye-ERW ayibonakali kakhulu, ngelixa ii-welds ze-SAW zihlala zirhabaxa kwaye zibonakala ngakumbi ngenxa ye-SAW.

Imbonakalo yoMphezulu

Umphezulu uya kuba nesiphelo esigudileyo esihambelana nendlela yokuvelisa esetyenzisiweyo;

Ukuba ubukhulu bungaphakathi kokunyamezela, ama-bumps, grooves, okanye i-grooves e-shallow longitudinal ephuma kwinkqubo yokuvelisa ivumelekile.

Iigalvanized

Iimveliso kwi-BS EN 10210 zilungele unyango lwediphu eshushu.

I-EN ISO 1461 kufuneka isetyenziswe ukucacisa iimfuno zokugquma.

Iingubo ze-Zinc zisetyenziselwa ukucwiliswa kwisisombululo esityhidiweyo esiqulethe ubuncinane i-98% ye-zinc content.

Ukulungiswa kweziphene zoMphezulu

Iziphene zobuso zingasuswa ngokusila ngumvelisi, ngaphandle kokuba ubungqingqwa obulungisiweyo abukho ngaphantsi kobuncinci obuvumelekileyo.

Ukuba yenziwe yinkqubo ye-welding, ukulungiswa kwee-welds akuvumelekanga ngaphandle kwe-arc welding ephantsi kwamanzi.

Umbhobho wentsimbi ongeyo-alloyi unokulungiswa ngokuwelda umzimba wombhobho.Umbhobho wentsimbi yealloyi awunakulungiswa ngokuwelda umzimba.

I-BS EN 10210 Ukumakisha

Imixholo yokumakishwa kombhobho wentsimbi kufuneka iqulathe:

ligama lentsimbi, umz. EN 10210-S275JOH.

ligama okanye uphawu lokuthengisa lomenzi.

ikhowudi yokuzazisa, umz. inombolo ye-odolo.

I-TS EN 10210 iityhubhu zensimbi zinokumakishwa ngeendlela ezahlukeneyo zokuqinisekisa ukuchongwa ngokulula kunye nokulandeleka, nokuba kupeyinti, isitampu, iileyibhile ezincamathelayo, okanye iilebhile ezongezelelweyo, ezinokusetyenziswa ngokwahlukeneyo okanye ngokudibeneyo.

Usetyenziso

Ngenxa yamandla ayo aphezulu, ukuqina okuhle, kunye ne-weldability, i-BS EN 10210 iyakwazi ukumelana noluhlu olubanzi lweemeko kunye neemeko zokulayisha kwaye isetyenziswa ngokubanzi kwiinkqubo ezahlukeneyo zesakhiwo.

Izakhiwo zokwakha: umz. amathambo ezakhiwo eziphakamileyo, izakhiwo zophahla lwamabala emidlalo, kunye nezinto ezixhasayo kwiibhulorho.

Imekhenikhali yenjineri: izakhelo kunye nenkxaso koomatshini kunye nezixhobo ezinzima.

Injineri yezendlela: njengeenkxaso zetonela, iikholamu zebhulorho, kunye nezinye izakhiwo ezithwele umthwalo.

Izibonelelo zezothutho: kubandakanywa amacandelo eendlela kunye neebhulorho zikaloliwe.

Icandelo lamandla: umz. iinqaba zeinjini yeinjini yomoya kunye namanye amalungu olwakhiwo loncedo lwamandla.

Singumvelisi wemibhobho yentsimbi yekhabhoni ekumgangatho ophezulu odityanisiweyo kunye nomthengisi ovela eChina, kunye nesitokhwe semibhobho yentsimbi engenamthungo, ekunika uluhlu olubanzi lwezisombululo zemibhobho yentsimbi!

Iithegi: bs en 10210, en 10210,s275j2h,s275j0h,s355j2h.

Ixesha lokuposa: Apr-25-2024