I-BS EN 10219 yentsimbiyintsimbi epholileyo eyakhiweyo yolwakhiwo olungenamngxunya eyenziwe kwiintsimbi ezingeyo-alloyi kunye ne-fine-grained ukwenzela ukusetyenziswa kwezakhiwo ngaphandle konyango lobushushu olulandelayo.

I-EN 10219 kunye ne-BS EN 10219 yimigangatho efanayo kodwa inemibutho eyahlukeneyo.

Amaqhosha okukhangela

Ulwahlulo lwe-BS EN 10219

BS EN 10219 Ubungakanani Uluhlu

IMathiriyeli ekrwada kunye neMiqathango yokuhanjiswa

I-BS EN 10219 Igama leNsimbi

Ukubunjwa kwemichiza ye-BS EN 10219

IiPropati zoomatshini ze-BS EN 10219

Iimvavanyo zempembelelo

Uvavanyo olungonakalisi

Inkangeleko kunye nokulungiswa kwesiphako

Ukunyamezelwa kweDimensional

Iigalvanized

I-BS EN 10219 Ukumakisha

Usetyenziso

Iimveliso zethu ezinxulumeneyo

Ulwahlulo lwe-BS EN 10219

NgoHlobo Lwentsimbi

Iintsimbi ezikhethekileyo ezingafakwanga kunye nezidibeneyo.

Iintsimbi ezingalukwanga:

S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H,S275NH, S275NLH, S355NH, S355NLH.

Iintsimbi ezidityanisiweyo ezikhethekileyo:

S460NH, S460NLH, S275MH, S275MLH, S355MH, S355MLH, S420MH, S420MLH, S460MH, S460MLH.

Indlela elula yokuxelela umahluko: iintlobo zetsimbi eziqukethe i-M okanye i-4 ziyi-alloys, kunye neempawu ze-alloying zensimbi zinokuqatshelwa ngokukhawuleza.

NgeNkqubo yokuVelisa

Iinkqubo zemveliso ezisetyenziselwa ukwenza imibhobho yentsimbi ngokwe-BS EN 10219 ibandakanyaI-Welding Resistance Welding (ERW) kunye ne-Summerged Arc Welding (SAW).

I-SAW ingahlelwa ngakumbi kwi-Longitudinal Submerged Arc Welding (LSAW) kunye ne-Spiral Submerged Arc Welding (SSAW) ngokusekwe kuhlobo lwe-weld seam.

NgokweMilo enqamlezileyo

CFCHS: Ingqele eyenziwe yamacandelo avulekileyo ajikelezayo;

I-CFRHS: Indawo ebandayo eyenziwe isikweri okanye uxande;

I-CFEHS: Amacandelo akwimigongxo abandayo;

Eli phepha ligxininisa kwi-CFCHS (iCandelo eliQhelekileyo eliyiSetyhula eliHollow).

BS EN 10219 Ubungakanani Uluhlu

Ubunzima bodonga: T ≤ 40mm

Idayamitha yangaphandle (D):

Umjikelezo (CHS): D ≤ 2500 mm;

Isikwere (RHS): D ≤ 500 mm × 500 mm;

Uxande (RHS): D ≤ 500 mm × 300 mm;

I-Oval (EHS): D ≤ 480 mm × 240 mm.

IMathiriyeli ekrwada kunye neMiqathango yokuhanjiswa

Iintsimbi ezingenalo ialloy

ngokweSihlomelo A, siSongwa okanye siMiselweyo/EsiQingiweyo esiQhelekileyo (N) seJR, J0, J2, kunye ne-K2iintsimbi;

Iintsimbi eziziinkozo ezintle

NgokweSihlomelo B, ukuRolwa okuMiselweyo/ okuMiselweyo (N) kweN kunye ne-NLiintsimbi;

NgokweSihlomelo B.M kunye neML, iintsimbi zaziqengqeleka nge-thermomechanically (M).

Amacandelo aholoholo aya kuhanjiswa akhiwe ngendlela ebandayo ngaphandle konyango olulandelayo lobushushu ngaphandle kokuba umthungo we-weld unokuba kwimeko ene-welded okanye ephathwa bubushushu.

Kumacandelo angenanto ye-SAW ngaphezu kwe-508 mm ngaphandle kobubanzi, kunokuba yimfuneko ukwenza umsebenzi ofudumeleyo wokubunjwa, ongachaphazeli iimpawu zomatshini, ukuze uhlangabezane neemfuno zokunyamezela ngaphandle kokujikeleza.

I-BS EN 10219 Igama leNsimbi

Ingqungquthela yamagama ye-BS EN 10219 iyafanaI-BS EN 10210, esebenzisa umgangatho we-EN10027-1.

Kumacandelo angenawo alloy ensimbi, ukutyunjwa kwensimbi kuqulethwe

Umzekelo: Intsimbi yolwakhiwo (S) enobuncinane obuchaziweyo bamandla esivuno sobukhulu obungekho ngaphezulu kwe-16 mm ye-275 MPa, enexabiso eliphantsi lempembelelo ye-eneji eyi-27 J ku-0 ℃(J), icandelo elimngxuma (H).

I-BS EN 10219-S275J0H

Ibandakanya iinxalenye ezine:S, 275, J0, kunye noH.

1. S: ibonisa ukuba intsimbi yolwakhiwo.

2. Ixabiso leenombolo (275): ubukhulu ≤ 16mm kumlinganiselo omncinci ochaziweyo wamandla esivuno, kwi-MPa.

3. JR: ibonisa ukuba kwiqondo lokushisa kwigumbi elineempembelelo ezithile;

J0: ibonisa ukuba ku-0 ℃ ngeempawu zempembelelo ezithile;

J2 or K2: iboniswe kwi -20 ℃ eneempawu zempembelelo ezithile;

4. H: ibonisa amacandelo angenanto.

Amacandelo entsimbi yolwakhiwo lwentsimbi ecolekileyo, ukutyunjwa kwentsimbi kubandakanya

Umzekelo: Intsimbi yolwakhiwo (S) enobuncinane obuchaziweyo bamandla esivuno sobukhulu obungekho ngaphezulu kwe-16 mm ye-355 MPa. Isondlo esiqhelekileyo sentsimbi yengqolowa ecolekileyo (N), enexabiso eliphantsi lempembelelo ye-eneji eyi-27 J ku -50 ℃(L), icandelo elinomgongxo (H).

EN 10219-S355NLH

Inezahlulo ezintlanu:S, 355, N, L, kunye noH.

1. S: ibonisa intsimbi yolwakhiwo.

2. Ixabiso lamanani(355): ubukhulu ≤ 16mm ubuncinane obuchaziweyo amandla esivuno, iyunithi yiMPa.

3. N: ukuqengqeleka okusemgangathweni okanye okusemgangathweni.

4. L: iipropati zempembelelo ezithile kwi -50 °C.

5. H: ibonisa icandelo elingenanto.

Ukubunjwa kwemichiza ye-BS EN 10219

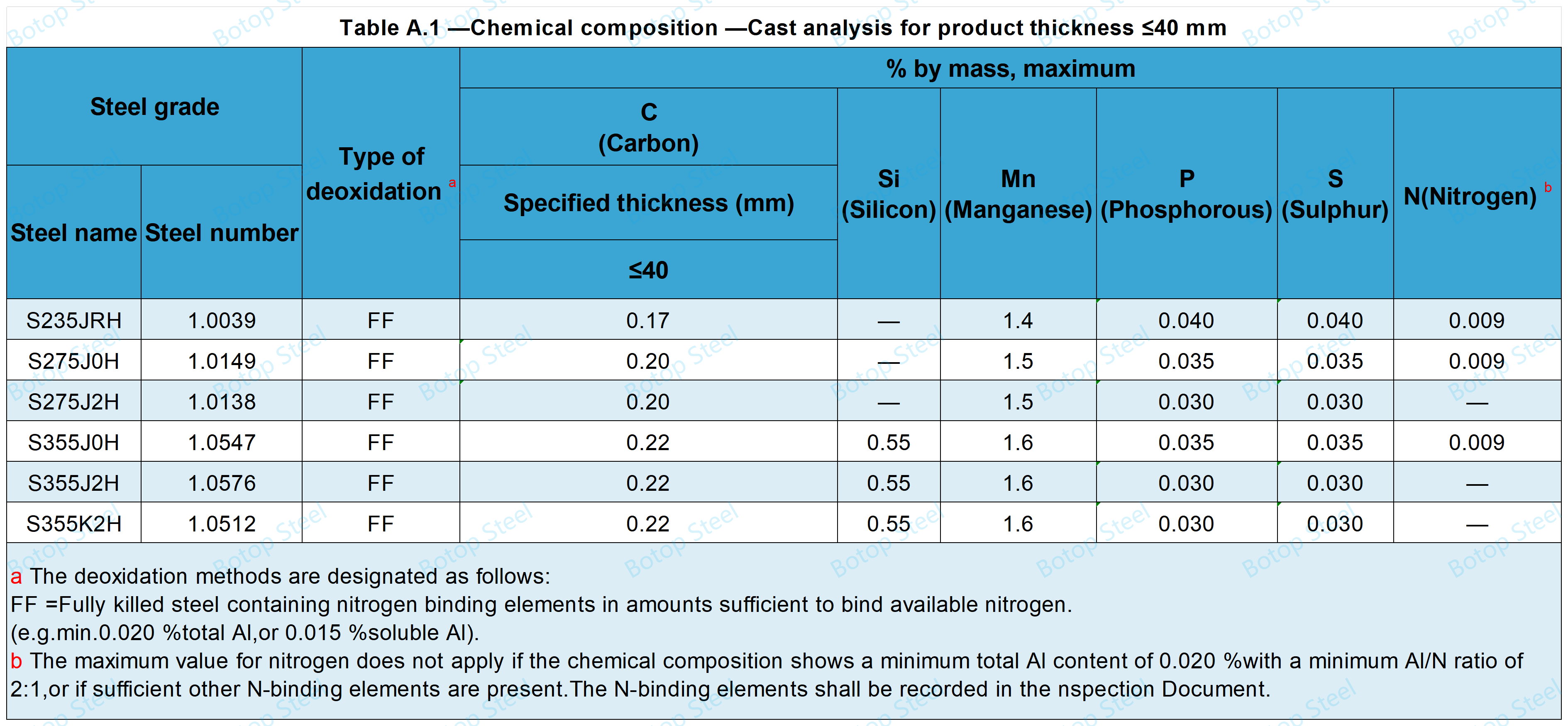

Iintsimbi ze-non-alloy - Ukubunjwa kweMichiza

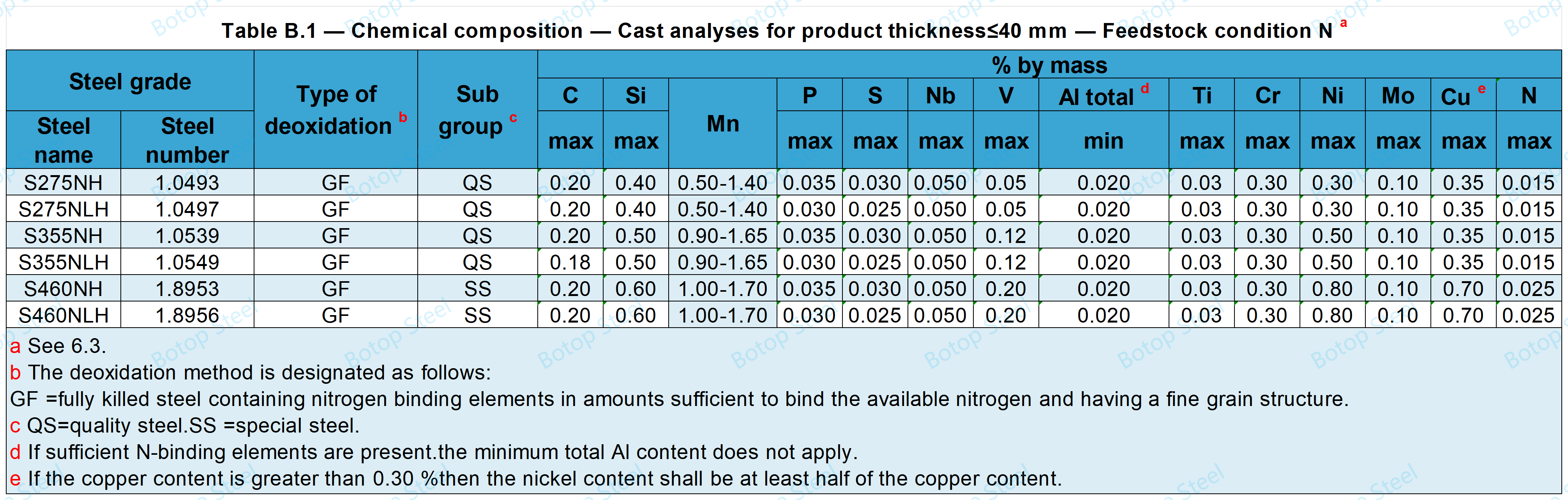

Fine Grain Steels - Ukubunjwa kwemichiza

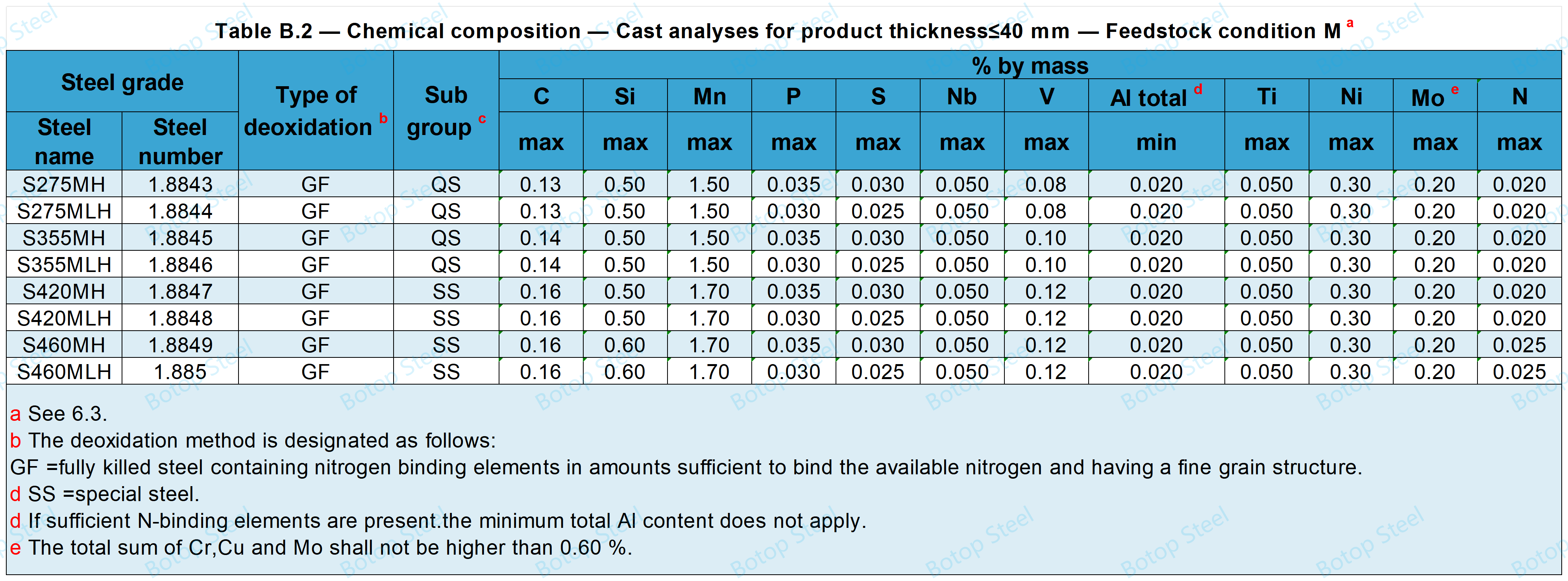

Xa i-fine-grained steel isetyenziswe njengento eluhlaza, ingahlelwa kwi-M kunye ne-N ngokwemiqathango yokuhanjiswa, kwaye iimfuno zokubunjwa kweekhemikhali zezi ntlobo zimbini zinokuhluka.

Xa kumiselwa i-CEV le fomyula ilandelayo iya kusetyenziswa: CEV=C+Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15.

Imeko yesondlo N

Imeko yesondlo M

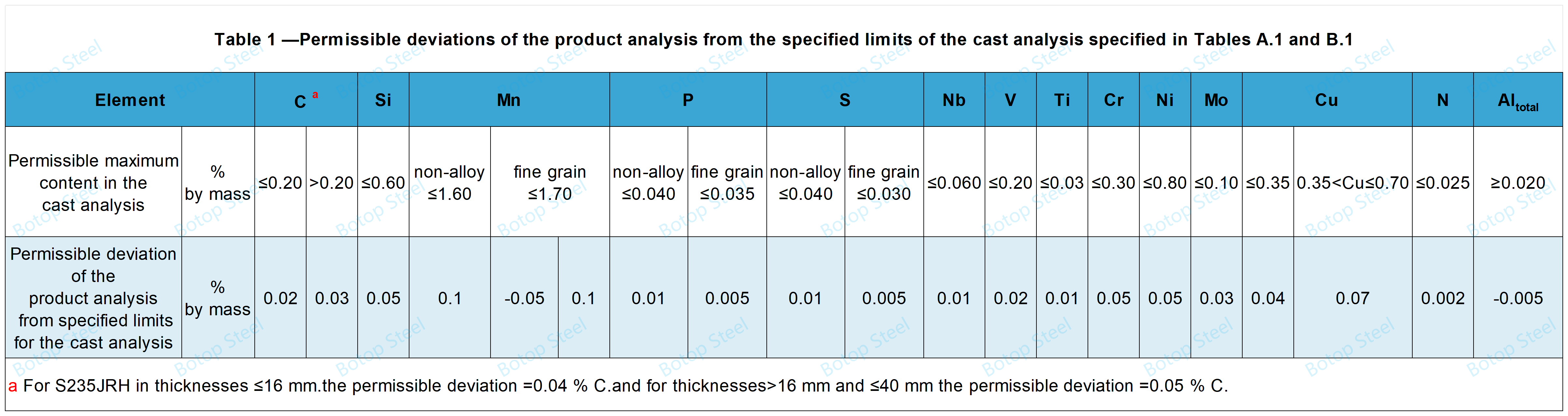

Ukutenxa ekuBumbeni kweMichiza

IiPropati zoomatshini ze-BS EN 10219

Kufuneka iqhutywe ngokuhambelana ne-EN 1000-2-1.Uvavanyo luya kwenziwa kuluhlu lobushushu ukusuka kwi-10°C ukuya kuma-35°C.

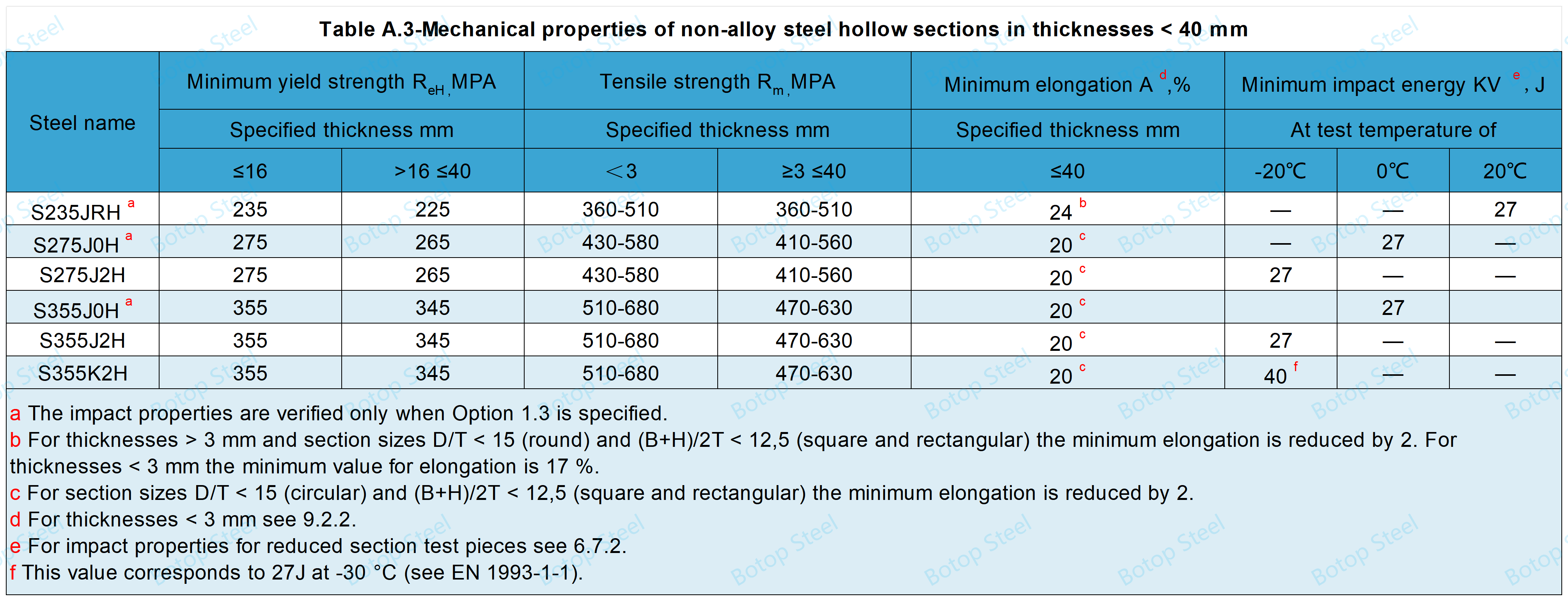

Iintsimbi ze-non-alloy - iiPropati zoomatshini

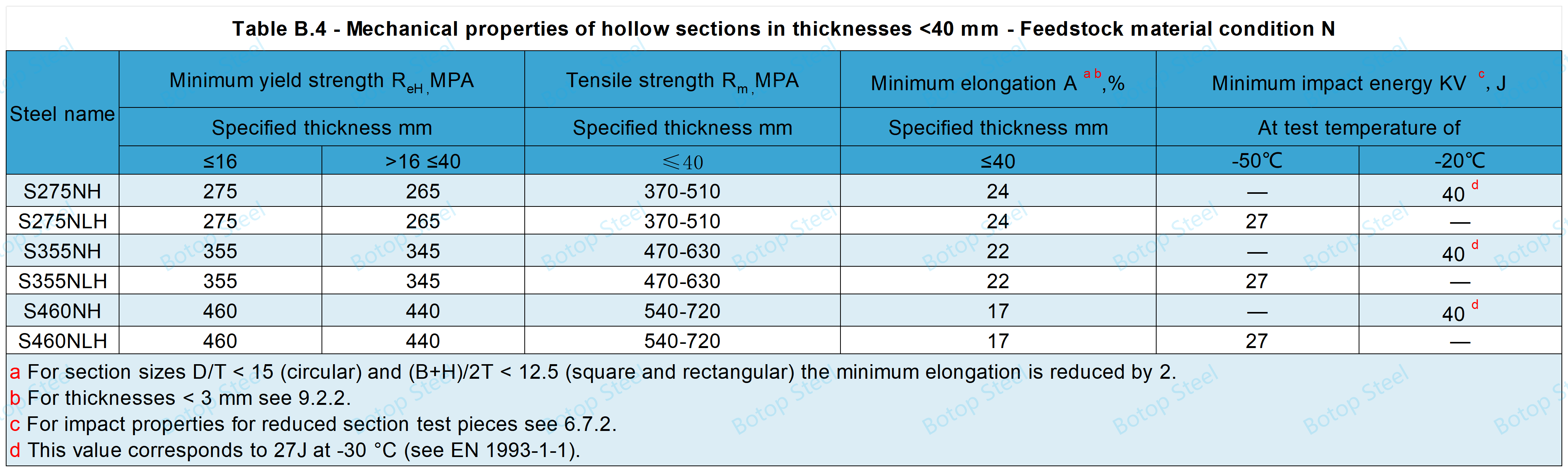

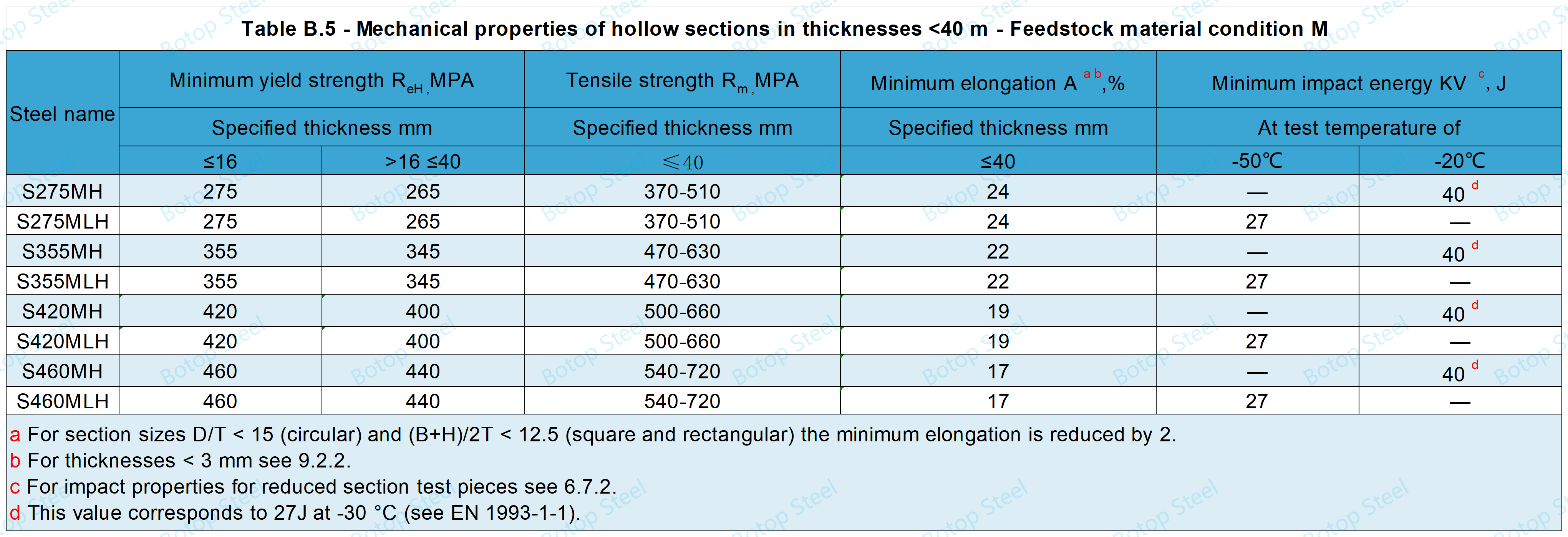

Fine Grain Steels - Mechanical Properties

Xa i-fine-grained steel isetyenziswe njengento eluhlaza, inokuthi ihlelwe kwi-M kunye ne-N ngokwemiqathango yokuhanjiswa, kwaye iimpawu zomatshini zezi ntlobo zimbini zinokuhluka.

Imeko yesondlo N

Imeko yemathiriyeli ye-Feedstock M

Iimvavanyo zempembelelo

Uvavanyo lwempembelelo luya kwenziwa ngokuhambelana ne-EN 10045-1.

Umyinge wexabiso leseti yeesampulu ezintathu ziyakulingana okanye zibe nkulu kunexabiso elikhankanyiweyo.

Ixabiso lomntu linokuba ngaphantsi kwexabiso elichaziweyo, kodwa alikho ngaphantsi kwe-70% yelo xabiso.

Uvavanyo olungonakalisi

Xa usenza i-NDT kwiiwelds kumacandelo esakhiwo esingenanto, ezi mfuno zilandelayo kufuneka kuhlangatyezwane nazo.

Amacandelo adityanisiweyo oMbane

Zifezekise enye yezi mfuno zilandelayo:

a) I-EN 10246-3 ukuya kwinqanaba lokwamkelwa kwe-E4, ngaphandle kokuba umbhobho ojikelezayo/ubuchule bekhoyili yepanekuku abuyi kuvunyelwa;

b) EN 10246-5 kwinqanaba lokwamkelwa F5;

c) EN 10246-8 ukuya kwinqanaba lokwamkelwa kwe-U5.

Amacandelo afakwe kwi-Arc eWelded

Umthungo odityanisiweyo we-arc entywiliselweyo wamacandelo angaphakathi uya kuvavanywa ngokuhambelana ne-EN 10246-9 ukuya kwinqanaba lokwamkelwa kwe-U4 okanye ngeradiyografi ngokuhambelana ne-EN 10246-10 kunye neklasi yomgangatho we-R2.

Inkangeleko kunye nokulungiswa kwesiphako

Imbonakalo yoMphezulu

Amacandelo angenanto aya kuba nomphezulu ogudileyo ohambelana nendlela yokuvelisa esetyenziswayo;amaqhuma, iigrooves okanye iigrooves zelongitudinal ezingenzulwanga eziphuma kwinkqubo yokwenziwa zivumelekile ukuba ubungqingqwa obushiyekileyo buphakathi kokunyamezelana.

Iziphelo zecandelo elinomngxuma ziya kunqunyulwa ngokufanelekileyo kwi-axis yemveliso.

Ukulungisa isiphene

Iziphene zobuso zingasuswa ngokusila ngaphandle kokuba ubukhulu bungekho ngaphantsi kobuncinci obuvumelekileyo obuchazwe kwi-BS EN 10219-2 emva kokulungiswa.

Kumacandelwana agayiweyo agayiweyo, ukulungiswa komzimba ngokuwelda akuvumelekanga ngaphandle kokuba kuvunyelwene ngenye indlela.

Iinkqubo zokulungisa i-Weld ziya kuhambelana neemfuno ze-EN ISO 15607, EN ISO 15609-1, kunye ne-EN ISO 15614-1.

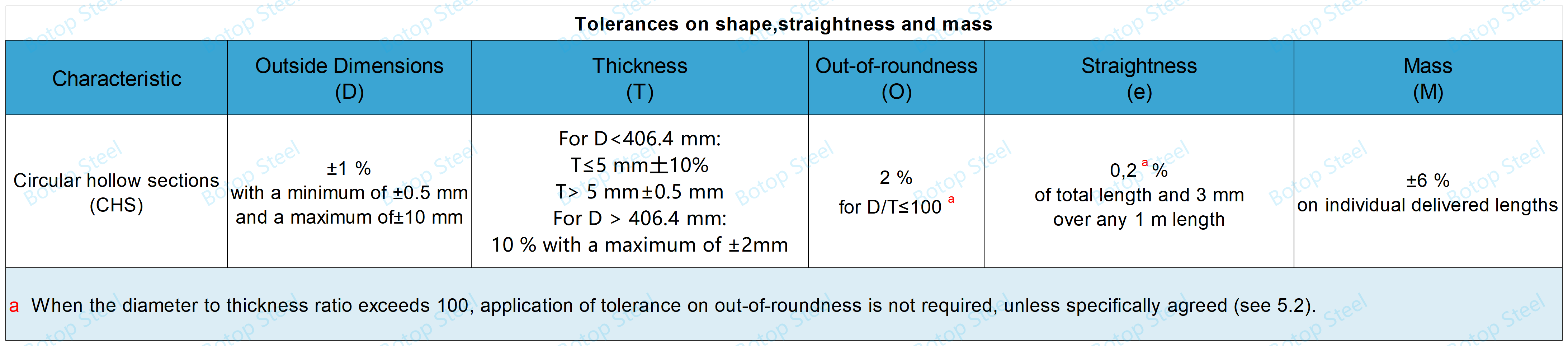

Ukunyamezelwa kweDimensional

Ukunyamezela komgangatho kuya kuhambelana neemfuno ezihambelanayo ze-EN 10219-2 kwaye ingqalelo iya kuhlawulwa kwimilo yecandelo lomnqamlezo.

Ukunyamezelana kwiMilo, ukuTwa kunye noMisa

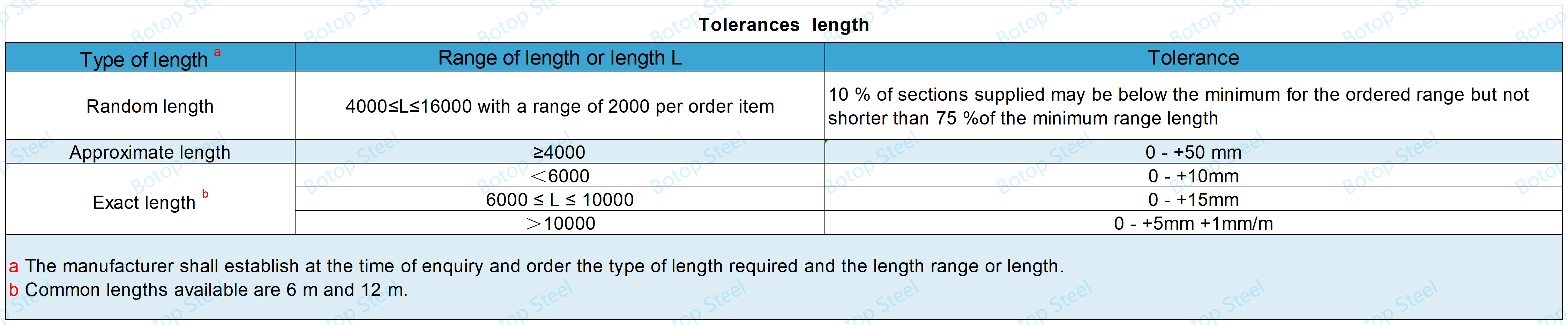

Ukunyamezela Ubude

Umthungo Ubude be-SAW Weld

Ukunyamezelana kubude bomthungo we-weld wangaphakathi nangaphandle we-arc entywiliselwe amacandelo aholoholo.

| Ukutyeba, T | Ubude be-weld bead, mm |

| ≤14,2 | 3.5 |

| >14,2 | 4.8 |

Iigalvanized

I-BS EN 10219 Ityhubhu enomgongxo inokuba shushu-diphu ifakwe igalvan ukuze isebenze ubomi obude.

Iityhubhu ezingenanto zityiswa kwibhafu equlethe ubuncinane i-98% ye-zinc content ukuze yenze umaleko wegalvanized.

I-BS EN 10219 Ukumakisha

Imixholo yokumakishwa kombhobho wentsimbi kufuneka iqulathe:

Igama lentsimbi, umz. EN 10219-S275J0H.

Igama okanye uphawu lokuthengisa lomenzi.

Ikhowudi yokuzazisa, umz. inombolo yeodolo.

I-TS EN 10219 iityhubhu zentsimbi zinokumakishwa ngeendlela ezahlukeneyo zokuqinisekisa ukuchongwa ngokulula kunye nokulandeleka, nokuba kupeyinti, isitampu, iileyibhile zokuncamathelisa, okanye iilebhile ezongezelelweyo, ezinokusetyenziswa ngokwahlukeneyo okanye ngokudibeneyo.

Usetyenziso

Ukusetyenziswa komgangatho we-BS EN 0219 ibandakanya yonke imimandla yeemfuno zentsimbi.

Ulwakhiwo:Imibhobho yentsimbi ye-BS EN 10219 isetyenziswa ngokubanzi kwiiprojekthi zokwakha, ezinjengokwakha iibhulorho, inkxaso yezakhiwo, njl.

Ulwakhiwo lweziseko zophuhliso: zisetyenziswa kwiiprojekthi zolondolozo lwamanzi, ulwakhiwo lweendlela, iinkqubo zemibhobho, kunye nezinye iiprojekthi zokwakha iziseko ezingundoqo, ezifana nemibhobho yokuhambisa amanzi, imibhobho yamanzi, njalo njalo.

Ukwenziwa kwemveliso: Le mibhobho yentsimbi ikwasetyenziswa xa kusenziwa izixhobo zoomatshini, iisistim zokuhambisa, kunye nezinye izinto ezisetyenziswa kwimizi-mveliso.

Ubunjineli bakamasipala: Kubunjineli bomasipala basezidolophini, i-BS EN 10219 imibhobho yentsimbi esemgangathweni ingasetyenziselwa ukuvelisa iileyili zokugada, iintsimbi, imiqobo yendlela, njalo njalo.

Ukuhlobisa kwezakhiwo: Uyilo lobuhle kunye namandla eetyhubhu zetsimbi zenza izinto eziqhelekileyo ezisetyenziselwa ukuhlobisa izakhiwo, ezifana nezitebhisi, ii-balustrades, iibrakethi zokuhlobisa, njl.

Iimveliso zethu ezinxulumeneyo

Ukususela ekusekweni kwayo kwi-2014, i-Botop Steel iye yaba ngumthengisi ohamba phambili we-carbon steel pipe eNyakatho ye-China, eyaziwa ngenkonzo yayo egqwesileyo, iimveliso ezikumgangatho ophezulu kunye nezisombululo ezibanzi.Uluhlu olubanzi lwemveliso yenkampani lubandakanyaingenamthungo, i-ERW, i-LSAW, kunye nemibhobho yentsimbi ye-SSAW, kunye nofakelo lwemibhobho, iiflange, kunye neentsimbi ezikhethekileyo.

Ngokuzibophezela okuqinileyo kumgangatho, iBotop Steel isebenzisa ulawulo olungqongqo kunye neemvavanyo zokuqinisekisa ukuthembeka kweemveliso zayo.Iqela layo elinamava libonelela ngezisombululo zobuqu kunye nenkxaso yeengcali, kugxilwe ekwanelisekeni kwabathengi.

Iithegi: bs en 10219, en 10219, chs, cfchs, s355j0h, s275j0h.

Ixesha lokuposa: Apr-26-2024